Author: Site Editor Publish Time: 2024-07-03 Origin: Site

Insulating glass adhesive can be divided into two categories: thermoplastic and thermosetting. Thermoplastic adhesives include hot melt butyl adhesive, polyisobutylene adhesive and comfort adhesive strip, while thermosetting adhesives include silicone adhesive, polyurethane adhesive and polysulfide adhesive.

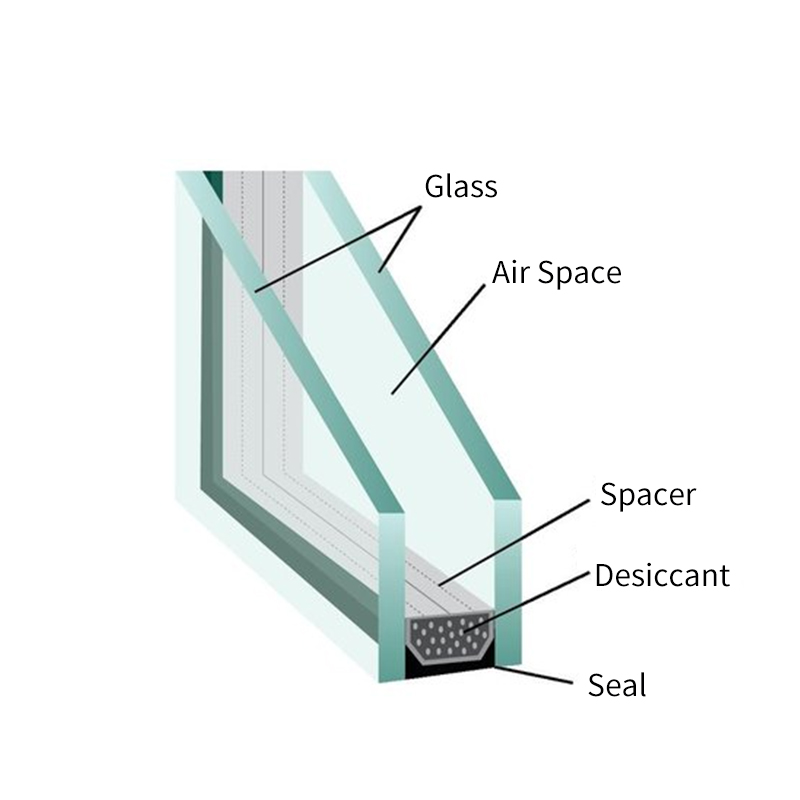

Insulating glass systems must use double-pass sealing, with the first sealant used to prevent the invasion of water vapor and the second sealant used to maintain the stability of the structure. Generally speaking, thermoplastic adhesives are mostly used for the first seal, while thermosetting adhesives are mostly used for the second seal, i.e. structural sealing.

Factors affecting Insulating glass adhesive

The curing of hollow glass glue is a chemical reaction process. Temperature has a great influence on its curing process. The use environment and protective environment will have a certain influence on the breaking time of hollow glue.

1. A high ambient temperature will shorten the breaking time. Air conditioning, heating, sunbathing and other methods can be used to keep the temperature and humidity of the use environment and protective environment within the appropriate range.

2. Too high a component ratio will shorten the breaking time. Adjust the two-group distribution ratio of hollow glue to make it within the range required by the hollow glue manufacturer.

3. When the summer formula glue is used in winter, the ambient temperature drops and the breaking time will be longer; while the winter formula glue is used in summer, the breaking time will be shortened due to the increase in ambient temperature.

4. The influence of pollutants, such as the use of other types or other brands of Insulating glass adhesive before the glue machine, the breaking time will be affected because the glue machine is not cleaned after the glue is changed. Therefore, try to use hollow glue with the corresponding season formula when using glue in winter and summer.